Best labeling head of its kind

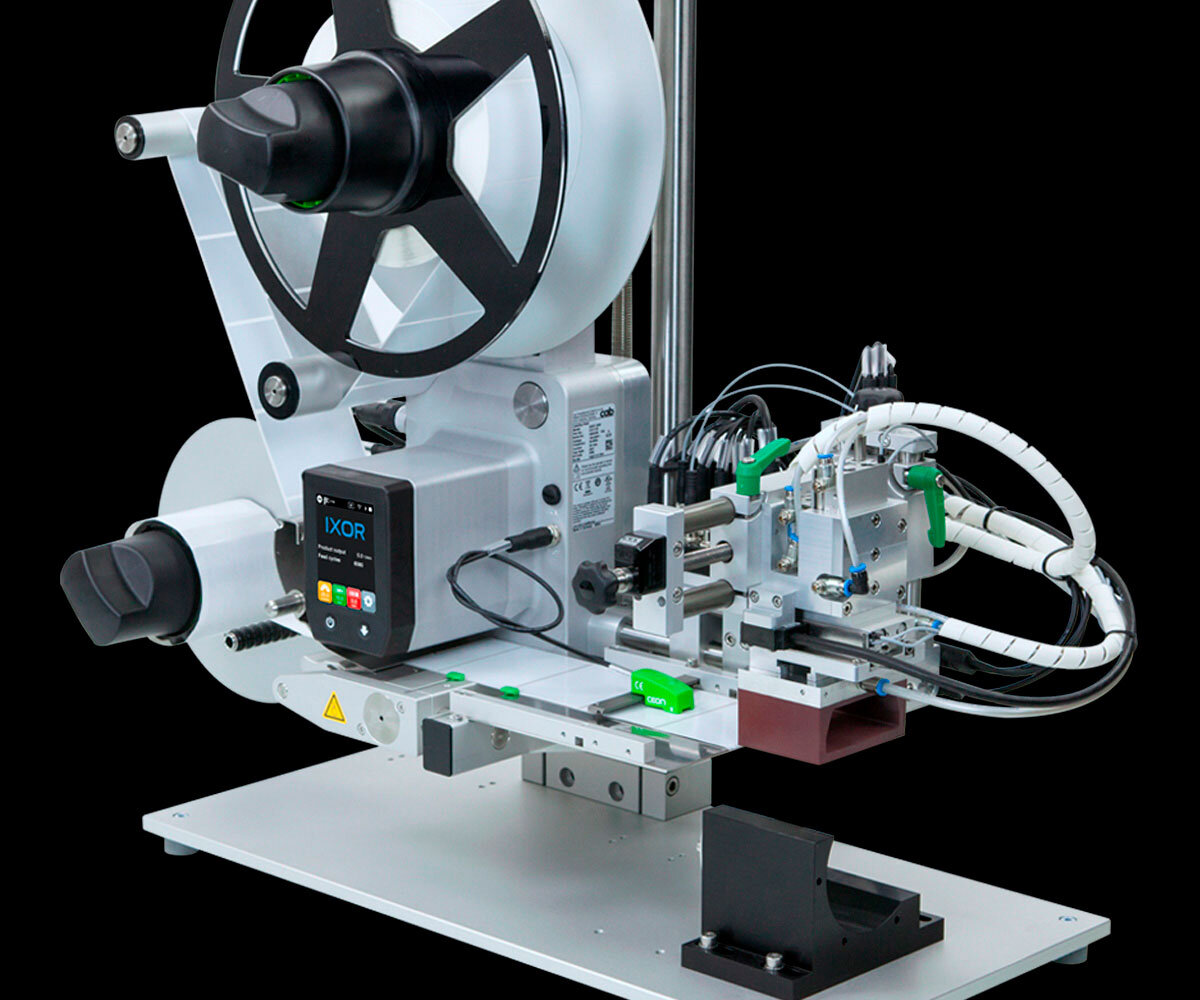

In 2009 cab had made the claim to develop the world's leading high-performance labeling head. In 2016, IXOR was introduced. It is first choice if self-adhesive labels must be applied in high quantities quickly and accurately to objects, either in continuous or clocked operation. TAG ON is contact point for all operations including a cab IXOR labeling head and its components, providing sales and technical service.

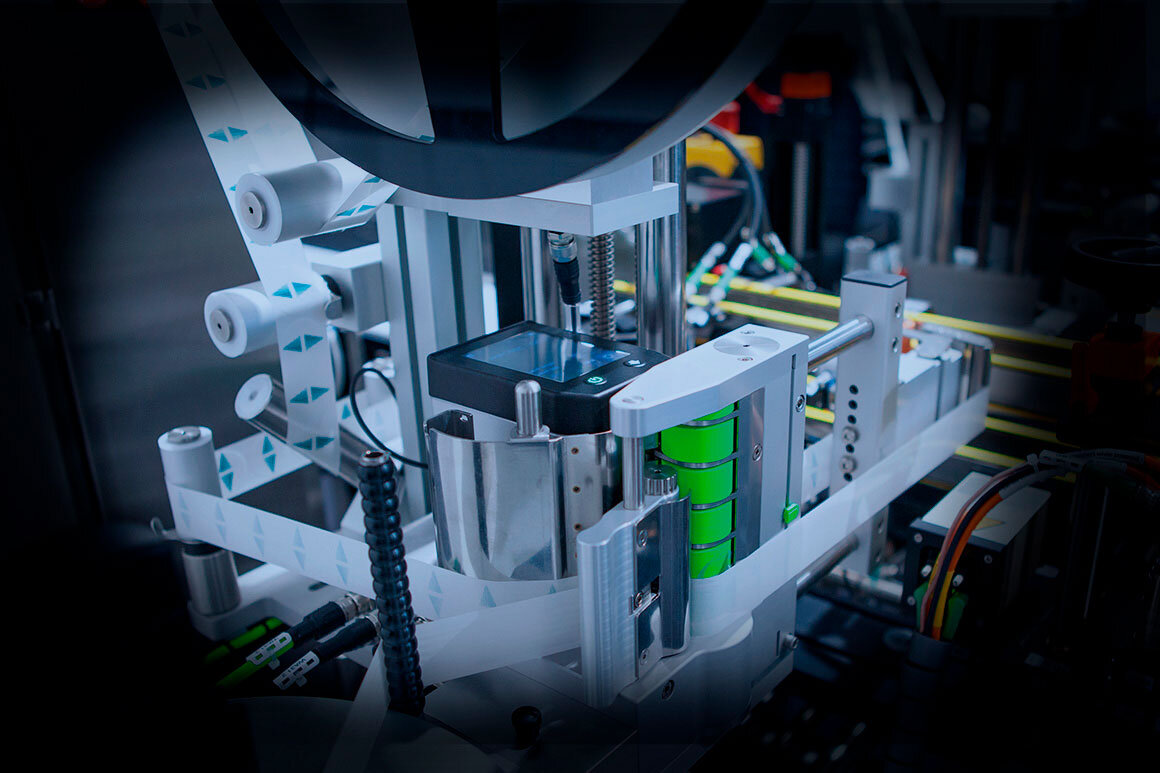

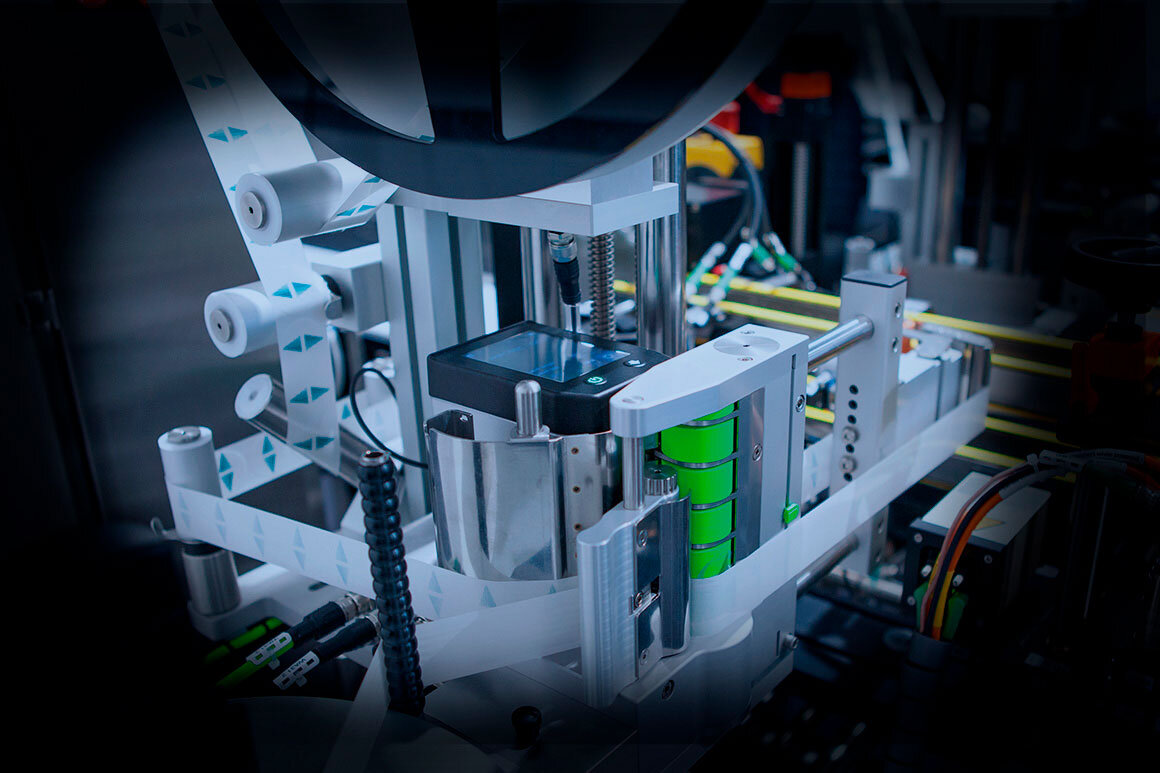

The base chassis is made of cast aluminum (IP66 and NEMA 250 level 12). It has the smallest constructional depth in this performance class and integrates the entire control system, power electronics and servo motor.

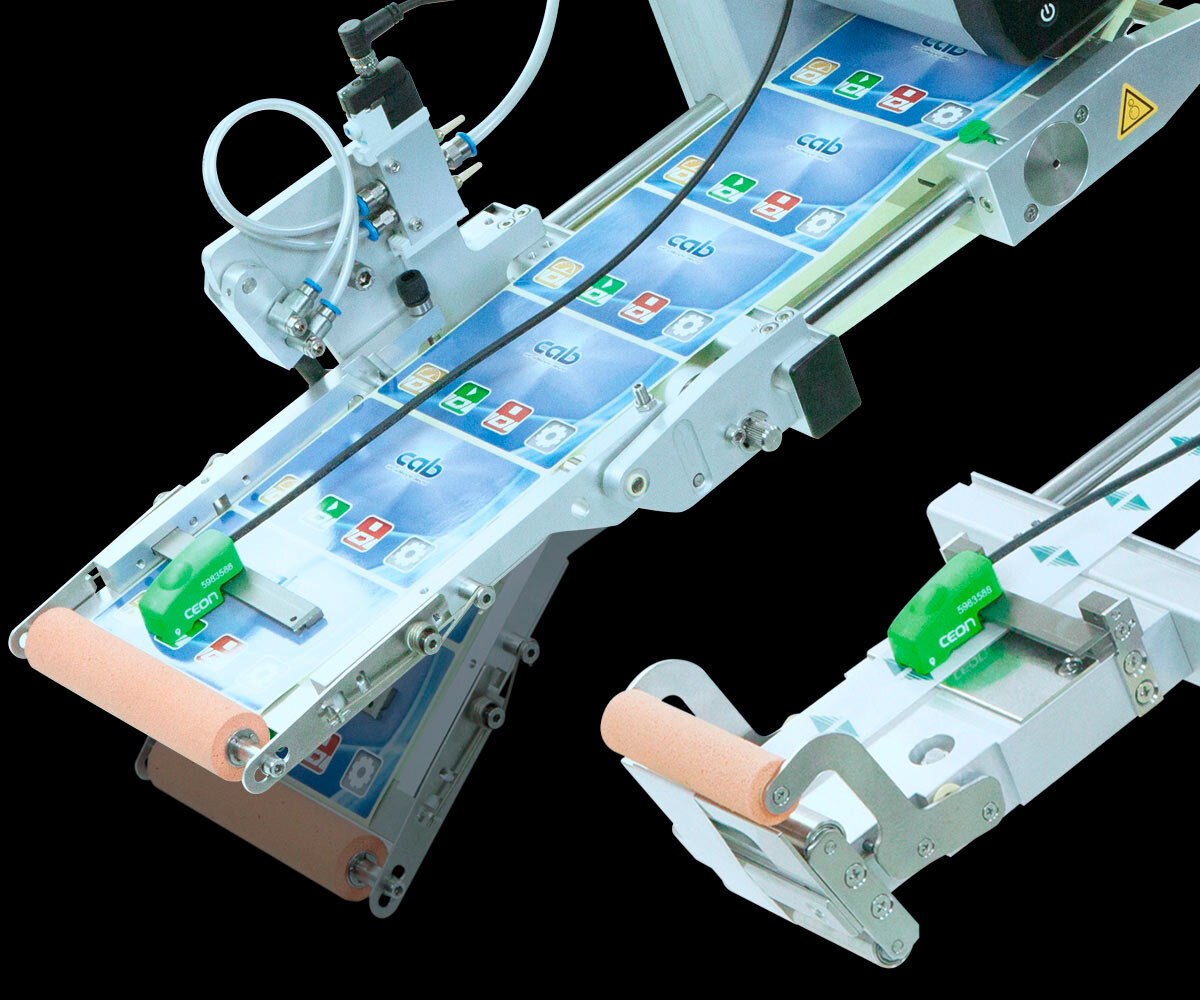

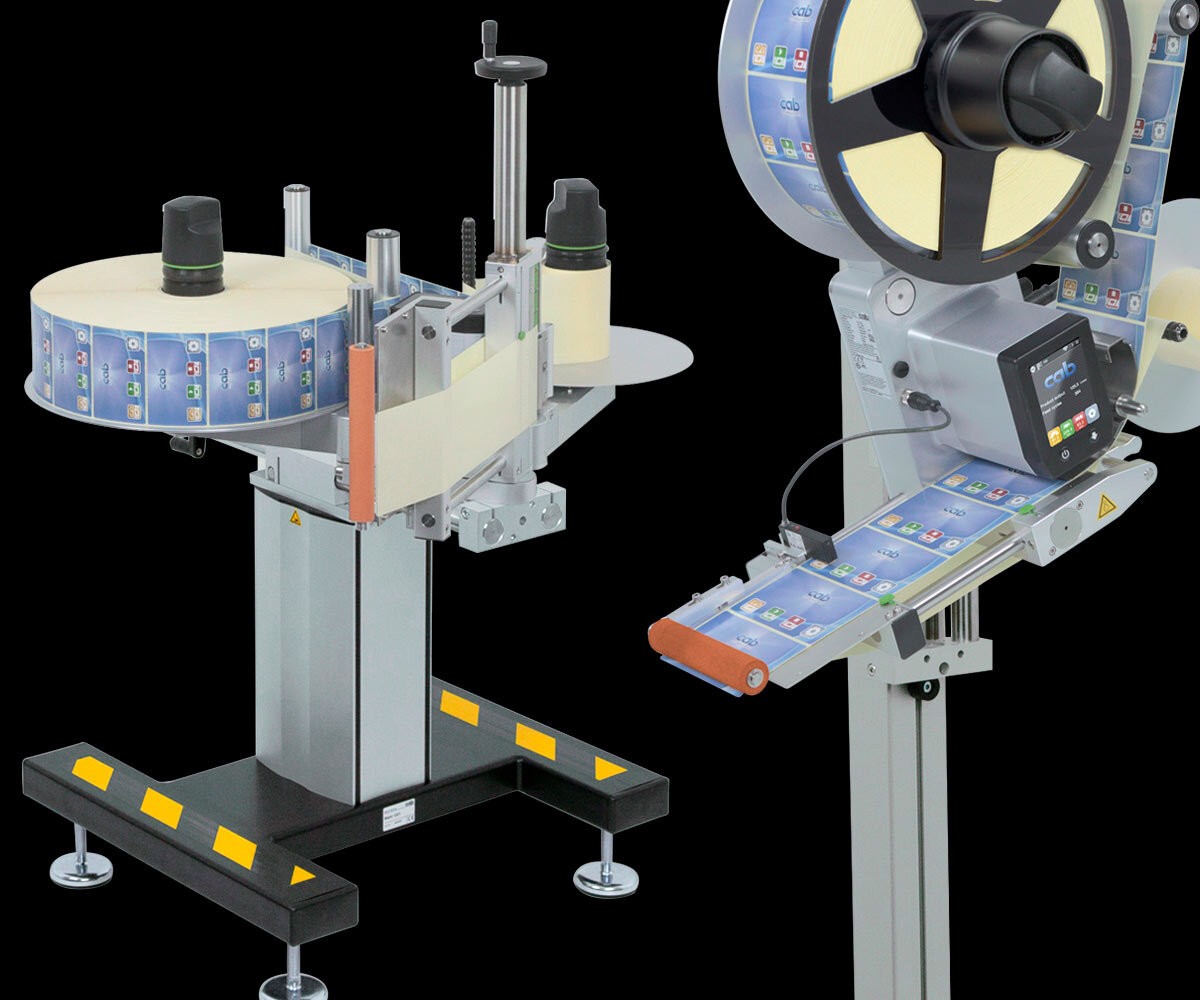

Integration to automatic labeling machines is possible, so is assembly to conveyor belts in manufacture or bottling plants. A wide range of accessories and stands support the assembly. Four structural widths are manufactured. Labeling heads are provided in left-hand or right-hand operation.

The CEON sensor detects each label to transfer next on the peel-off plate. Materials as thin as 0.05 mm, including opaque, transparent or metallic ones, are reliably verified at any label speed. If a label is missing on the liner tape, the next label is automatically transfered.

Interfaces required for network operation are provided, so are Industry 4.0 protocols. LAN or WLAN enable interchange with a control unit superior to machines in a plant. OPC UA secures such communication. MQTT, Modbus and EtherNet/IP are options.

Rugged construction and numerous approvals (CE; cULus; FCC Class A; ICES-3; IP66; UL50E; NEMA 12) enable operations in industry and logistics, the food or pharmaceutical sector, in the matters of identification or tamper evidence. Zero downtime can be achieved when operating a redundant system.

All components integrate a tailor-made drive. Depending on the configuration, materials and label size, a maximum of 2,400 labels per minute can be applied synchronously to the product speed. Label webs may run continuously with up to 3,300 mm/s (200 m/min), even on large label rolls.

An intuitive graphical user interface allows operating the device via the integrated touch display, or remote on a tablet, smartphone or PC using the web interface. Data backup and recovery are possible, so are firmware updates.

Mounting spots (100% compatible with competitive devices) enable attachment to bars. By moving the system along the integral adjusting axis, label positions on an object can be aligned transversely to its running direction.

IXOR and components